For logistics managers, nothing spells dread like the uncertainty of shipment locations and delivery schedules. As global supply chains continue to intertwine, maintaining visibility is non-negotiable.

If you’re looking for a versatile, cost-effective solution to elevate supply chain visibility, this article is for you.

We’ll explore how QR Codes can enhance supply chains, fostering transparency, mitigating risks, and building trust with stakeholders and customers.

Table of contents

1. How to integrate QR Codes into your supply chain

2. Benefits of using QR Codes in supply chain management

3. Best practices for using QR Codes to enhance supply chain visibility

How to integrate QR Codes into your supply chain

Let’s look at the step-by-step implementation of QR Code technology for tracking the flow of goods in a supply chain.

1. Choose a secure, reliable, and scalable QR Code generator

Before you begin, choose a QR Code generator with the following features:

- Provides API access and supports integrations with your current supply chain systems.

- Offers the ability to bulk generate QR Codes and label them to make searching, filtering, and analyzing them easier.

- Allows complete customization and editability, even after the QR Codes are generated.

🔥If you use Uniqode

Get access to APIs, bulk QR Code generator, and ample customization and editing capabilities. Uniqode is the only GDPR and SOC 2 Type 2 compliant solution ensuring the utmost data security. Moreover, you also get the support of 4000+ integrations via Zapier and Make.

2. Integrate the QR Code platform with a supply chain management software

If you already use a supply chain management system such as Zoho inventory, integrate it with your chosen QR Code platform via API.

Once you integrate, the software generates a unique QR Code for each asset, containing a link to its digital profile.

If you don’t currently use supply management software, you can still implement QR Code-based supply chain tracking in the following ways.

- Integrate QR Codes with Google Sheets. Each scan populates a new row in the spreadsheet with relevant data, including QR Code ID, timestamp, location, and more.

- Create a single or bulk dynamic QR Codes using your chosen QR Code generator and link them to a form. This form could be hosted on your website or a dedicated form-building platform. On scanning, users can update the asset-related information in the form.

Suggested read: Where to direct your QR Codes for asset tracking

3. Print QR Code labels and affix them to assets

Use a durable, tamper-proof adhesive to stick the QR Code asset labels. Also, ensure the QR Codes are prominently displayed and easily accessible on the asset.

4. Update asset information at each step in the supply chain

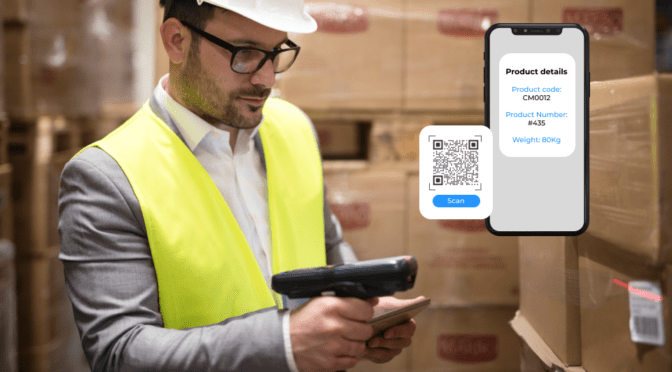

At each step in the supply chain, a team member can scan the QR Code with their mobile device and update the asset’s information within the software.

For instance, a warehouse worker scans a QR Code on a pallet of goods upon arrival. They instantly update the distribution management system with details about the received quantity, inspection status, and location within the facility.

The updated information is automatically synchronized with the central asset management database in real time and visible to all stakeholders.

🔥If you use Uniqode

You can track the IP and the exact GPS location of each scan.

When creating a new QR Code, turn on GPS location under “Advanced Analytics.”

Users scanning the code simply allow location access when prompted.

The GPS tracking data becomes accessible in the “Analytics” section of the Uniqode dashboard or is automatically integrated with asset management software, ensuring up-to-the-minute insights and optimal supply chain visibility.

Benefits of using QR Codes for supply chain management

Here’s why QR Codes surpass traditional methods, such as barcodes and manual checks, for monitoring and tracking goods in supply chains.

1. Real-time insights

QR Code tracking offers an exceptional advantage in real-time traceability. QR Codes provide a digital trail that allows you to easily trace each product or batch’s journey.

In cases of recalls or quality issues, you can quickly pinpoint affected items, minimizing the scope and cost of recalls.

🧠 Did you know?

43% of manufacturers are using QR Codes to improve their logistics tracking.

Discover more such interesting insights in our State of QR Code Report!

2. Streamlined data collection

Traditional data collection methods for the supply chain often involve cumbersome paperwork and the inherent risk of human errors.

QR Codes simplify this process by data automation. With a quick scan, you can record critical information accurately and efficiently, eliminating the risk of data inaccuracies.

3. Cost-effective solution

Implementing QR Code tracking stands out for its cost-effectiveness when compared to many traditional inventory tracking systems.

There’s no need for expensive hardware or complex infrastructure. All that’s required is a mobile device or a handheld scanner, making it accessible to businesses of all sizes.

4. Enhanced customer trust

In the era of informed consumers who value transparency and traceability, QR Codes play a pivotal role.

Incorporating QR Codes into your supply chain allows you to share real-time tracking information with customers, fostering trust and demonstrating your unwavering commitment to quality.

Best practices for using QR Codes to enhance supply chain visibility

Here are some tried-and-true strategies for effective QR Code tracking in supply chains:

1. Standardize QR Code formats

Establish standardized QR Code formats for different types of assets and stages within the supply chain. Consistency in format simplifies scanning and data management.

2. Ensure QR Code quality

High-quality QR Codes are crucial for reliable scanning. Ensure that QR Code labels are clear, free from damage, and easily scannable, even in challenging conditions. Use an industrial label printer to print QR Codes, rather than regular printers.

3. Train personnel

Provide training to employees involved in QR Code scanning and data entry. Familiarity with the process and its importance ensures accurate and consistent data capture.

4. Prioritize data security

Prioritize data security by implementing encryption and access controls for QR Code tracking systems. Protect sensitive supply chain information from unauthorized access.

🔥If you use Uniqode

You can password-protect your QR Codes to control access.

While creating a new QR Code, go to the “Advanced Analytics” section and toggle the switch under “Password Protection.” Enter a password of your choice, and ensure that you choose a strong password at least six characters long.

Frequently asked questions

1. What is the use of QR Codes in logistics?

QR Codes in logistics serve as a quick and efficient method for tracking shipments, packages, and assets throughout the supply chain.

By scanning QR Codes on shipping labels or packages, logistics companies can access real-time information about the shipment’s status, location, and delivery schedule—facilitating smoother logistics operations.

2. What are the benefits of QR Codes in the warehouse?

QR Codes offer various benefits in warehouse management.

- Error minimization: QR Codes reduce manual data entry errors, ensuring accurate and up-to-date inventory records.

- Enhanced traceability: QR Codes create digital trails, simplifying item history tracing and issue resolution.

- Real-time updates: QR Codes provide instant inventory updates, empowering managers with real-time data for effective decision-making and resource allocation.

3. How are QR Codes used in manufacturing?

You can use QR Codes in manufacturing in the following ways:

- Quality control: QR Codes on products or components can link to quality control data, helping manufacturers ensure product quality and compliance with standards.

- Work instructions: Workers can access detailed work instructions, assembly guides, and manuals by scanning QR Codes, improving efficiency and reducing errors.

- Maintenance records: QR Codes on manufacturing equipment and machinery aid in tracking maintenance schedules, reducing downtime, and ensuring equipment reliability.

- Inventory management: QR Codes seamlessly integrate with supply chain software, providing real-time visibility into the movement of goods and materials.

4. Can QR Codes be used to track inventory?

Yes, QR Codes are highly effective for tracking inventory. Each item or product can have a unique QR Code that links to detailed information about the item, including its type, quantity, location, and status.

Warehouse staff and inventory managers can scan these QR Codes to update inventory records and monitor stock levels in real time.